Not all EV chargers are equal. Like EVs, they come in many different configurations and offer different features. Whether you’re shopping for a personal electric vehicle or you’re thinking about electrifying your fleet, sorting it all out can be a chore. Here we’ll briefly explain the different types of chargers, how they work, and what it all means for people who use their EVs for at home or for business.

To make sense of EV chargers, the EV industry created three “levels” of charging that roughly correlate to charging power and speed—level 1 being the lowest power/slowest speed. This gives us a straightforward way to categorize and organize EV chargers.

Level 1 charging is the slowest and most accessible form of charging. It uses the standard home wall outlet (120v in US, 220v in EU) and your EV’s onboard charging hardware to charge your EV’s batteries. Level 1 charging usually delivers around 3-5 miles (5-8 km) of range per hour of charging. Not great, but if you leave your EV plugged in overnight you’ll probably have enough power to get to work in the morning. On the other hand, if you’re going on a road trip, it could take more than 30 hours to get 105 miles (169 km) of range. Level 1 charging is slow, but it’s cheap—the equipment comes with your EV and all you really need is an extension cord. If you have a short commute or work from home, you may not need more than level 1 charging.

But if you have a longer commute, or if you can’t wait a few days to fully charge your EV, you’ll need something faster. And if you’re running a fleet, level 1 charging won’t delivery anywhere near the power you need.

Level 2 is the fastest way to charge your vehicle at home. It uses the 240v power lines in your home that are dedicated to high-power appliances like clothes dryers, electric ovens, or central air conditioners. These higher-voltage lines provide more current (amperage) than a standard wall outlet, which means you can charge your EV faster. A level 2 charger can fully charge most passenger EVs in 8-10 hours, which is about three times as fast as a level 1 charger.

Depending on your home, you may need to have an electrician install a second 240-volt power outlet with its own circuit breaker to use a level 2 charger. Some chargers need to be hard wired into your home’s electrical system by a certified electrician and may also require a separate circuit breaker. Many can be used without a dedicated circuit breaker at lower charging levels. It’s also possible to use your existing clothes dryer outlet, swapping out the dryer’s plug for your charger’s when you need to. But before you use any level 2 charger, it’s a good idea to have an electrician inspect your home’s electrical system to make sure it can handle the power draw. High-power chargers and appliances can overload your home’s wiring, causing blown circuit breakers or even fires.

Level 2 charging may work great at home, but it won’t deliver enough power for businesses or fleets. They require more power to charge batteries much faster.

Level 3 charging doesn’t really exist as a category—it’s just a convenient way to categorize everything faster than level 2 charging. When a company or publication mentions level 3 charging, they mean DC fast charging.

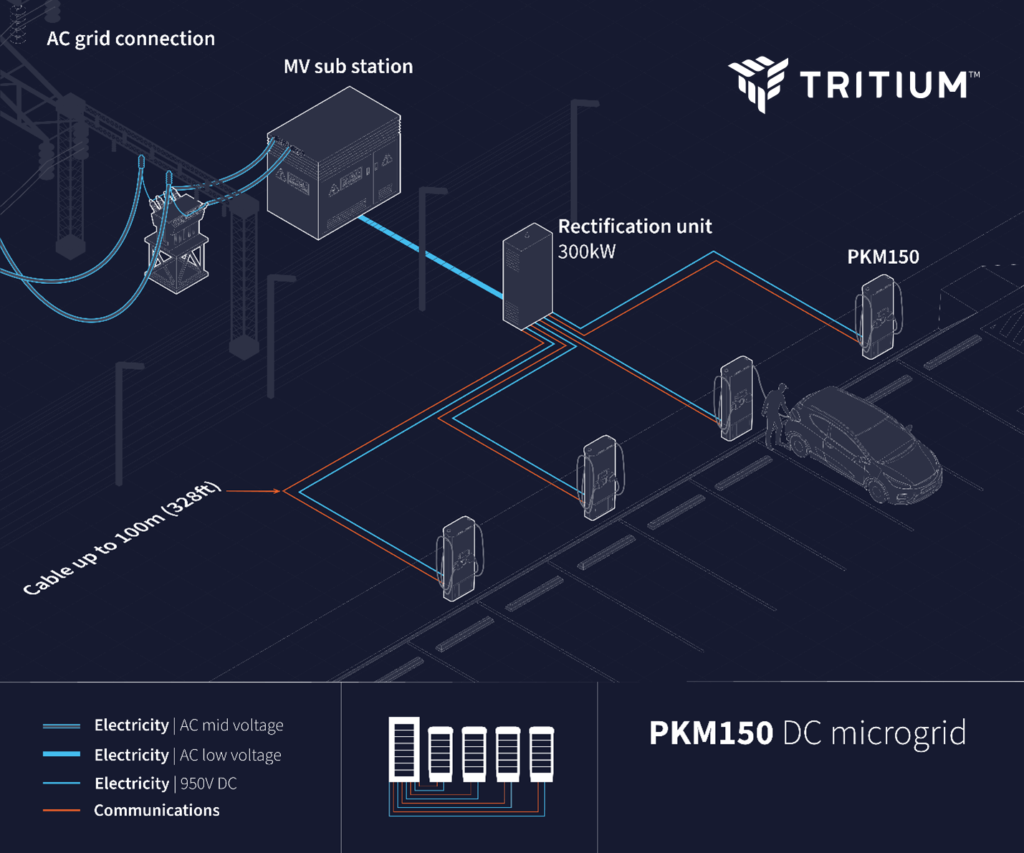

Direct current (DC) fast charging is the fastest way to charge up your EV. Lithium-ion batteries store and release DC power, and there’s no way to charge them without first transforming the alternating current (AC) power in the electrical grid to DC power. Level 2 home chargers can only handle so much power. Commercial DC fast chargers connect directly to high-voltage AC power lines and have dedicated infrastructure for transforming it into DC power. Because of this, they can deliver much more power than level 2 home chargers. DC fast chargers can typically charge an EV from 20 to 80 percent in as little as 15 minutes. They are perfect for highways, retail environments, delivery vehicles, and even electrical industrial equipment.

DC fast chargers like our PKM150 are a quick and convenient way for EV drivers to charge up while they’re shopping, taking a road trip, or even grabbing a bite to eat. They will also be essential to “last-mile” delivery EVs that deliver goods from local warehouses to homes and businesses. Walmart and Amazon have both purchased electric delivery vehicles for last-mile delivery and they plan to purchase more in the coming years.

For a deeper dive into how DC fast chargers work, read our article here.

Expect to see more DC fast chargers at shopping centers, restaurants, rest stops, gas stations, and even convenience stores. Unlike gas stations, they can be purchased and installed by any business who has the space to install them. Modular chargers like our PKM and RTM series can be purchased and installed in “base” configurations and then upgraded over time to meet increased demand. According to a recent BNEF report, the world will need approximately 290 million more electric vehicle (EV) charging points by 2040 to keep up with the growing global EV fleet. The U.S EV market alone is projected to grow from $28.24 billion in 2021 to $137.43 billion in 2028.

If you’re interested in installing a DC fast charger for your business, contact a member of our sales team today:

Filling up your car with gas is straightforward: Liquid gasoline flows out of the pump and into the tank. The flow rate is linear, meaning the amount of gas flowing out of the pump stays the same over time. You’d be surprised if the pump blasted 10 gallons of gas into the tank in the first few minutes, then took 30 minutes to fill up the rest. However, electric vehicle (EV) charging is non-linear, meaning the rate of energy flow from the charger to your car’s battery is not constant.

Lithium-ion batteries are far more complex and delicate than a simple gas tank. Charge them too quickly and they can get too hot or even be damaged. Overcharge them and they’ll be damaged. Let them sit without charging or discharging and they’ll lose capacity. To prolong battery life, EV manufacturers develop charging routines, or “curves,” to manage the charging process in the most optimal way and retain capacity over time. Now let’s learn why lithium-based batteries need charging curves and how EV makers and charger makers work together to deliver them.

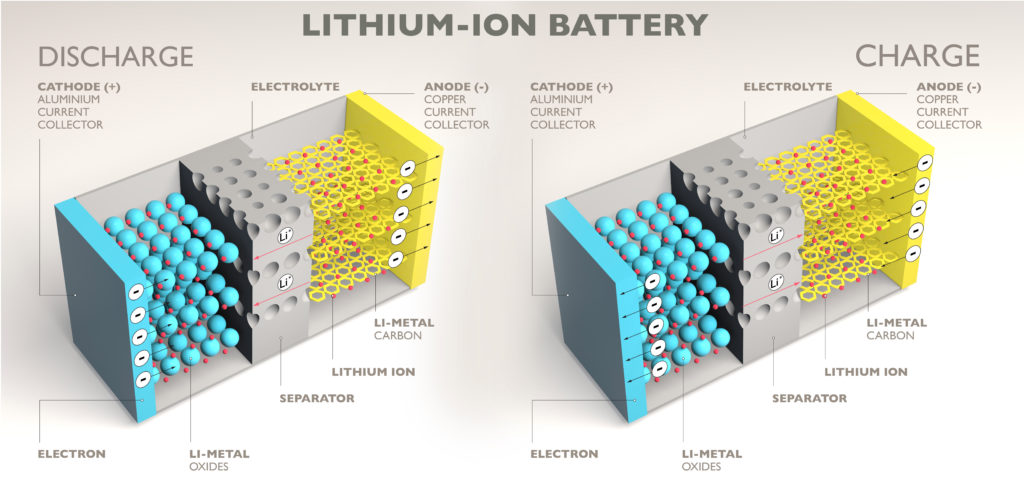

Very simply put, lithium-ion batteries store and release energy via a chemical reaction. During this reaction, lithium ions move from one electrode to the other through an electrolyte, either shedding or gaining electrons along the way. Run a current of electricity through the battery and it “charges.” Connect the terminals to a circuit and they discharge.

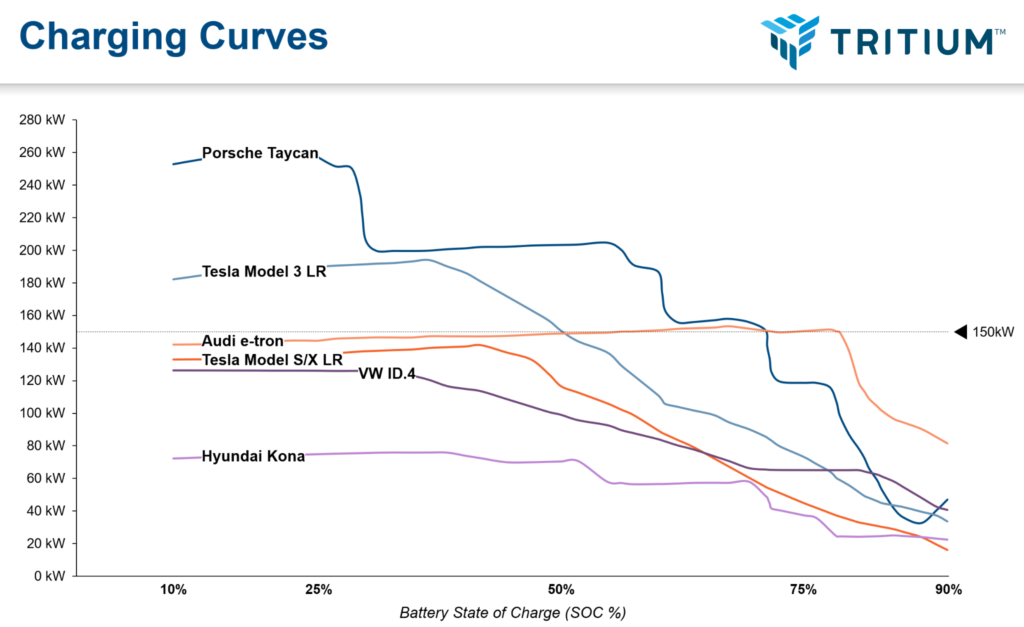

Charging and discharging lithium-ion batteries generates heat, and excessive heat can reduce long term battery life. Fast charging lithium-ion batteries is a delicate balance between speed and heat. Charge them too quickly and they’ll overheat. To keep batteries cool while charging them quickly, auto manufactures vary the amount of charge over time. Typically, fast charging has two phases, a constant current phase and a constant voltage or “topping charge” phase. During the constant current phase, the battery charges as fast as it can without overheating. You may have noticed that many EV manufacturers say their cars can fast charge from 20 to 80 percent in a short amount of time. That’s the constant current phase, which is the fastest in the charging cycle. After the constant current phase, the charger moves into the constant voltage phase, which is slower. Charging the EV battery from 80 to 90 percent may take as long as charging it from 40 to 80 percent. As the battery nears full charge, it’s critical to make sure it doesn’t overheat, thus charging is slower.

Every EV has its own unique charging curve. When you plug your EV into a DC fast charger, it tells the charger how it needs to be charged. Your car constantly communicates with the charger, relaying information about the battery’s current state of charge. This communication is key to maintaining battery temperature during charging, and the overall health and longevity of your car’s lithium-ion battery. Tritium chargers use multiple communication standards to communicate with cars, including DIN SPEC 70121, ISO 15118, and CHAdeMO. Different cars use different standards, but manufacturers are working to create a more universal experience through a standard called Plug & Charge.

With Plug & Charge, there’s no need to enter payment information. Payment and/or charging network membership info is stored onboard in the car and is transmitted securely to the charger instantly. The system uses cryptographic tools to secure communications between the vehicle and the charging station, protecting the driver’s personal information, the vehicle’s systems that are “touched” during the charging process, and the charger itself from malicious attacks during the charging process. Plug & Charge will make charging up your EV much faster, easier, and more convenient.

The power grid runs on alternating current (AC), but EVs use direct current (DC). Direct current does what it says: Flows in one direction directly. Alternating current flows in alternating directions, flip-flopping from one to the other, 50 or 60 times per second. AC is great for transmitting power over long distances, but it can’t be stored in a battery. To charge a battery, AC power needs to be changed into DC power. DC fast charger systems use something called a rectifier to transform AC power into DC power for charging. Rectifiers essentially redirect alternating current into a single-direction of flow—direct current. That DC current flows into the DC charger, which ensures the EV receives the right amount of power when it needs it.

If you’re considering an EV, you might want a home charger. To learn more about different charger types, check out our article on different levels of charging.

If you’re a business owner who’s interested in installing a DC fast charger, contact one of our experts today:

Tritium recently had the honour of hosting Sir Ian Botham! The English cricket legend, member of the House of Lords, cricket commentator, and ICC Cricket Hall of Fame member stopped by our Brisbane offices and factory to get an in-person look at Tritium’s DC fast charging technology.

Recently appointed UK Trade Envoy to Australia, Lord Botham is tasked with delivering an ambitious global trade agenda on behalf of the British government. His interest in technology associated with the movement to Net Zero led him to Tritium, where he had a chance to meet with some of the company’s senior leadership to learn about the company’s history, milestones, and upcoming activities.

UK Prime Minister’s Trade Envoy to Australia Lord Botham said, “Clean technology is key to making the transition to a greener economy and it’s been fascinating to see Tritium’s work. Electrifying the world’s transport is vital to achieving net zero emissions – and the UK’s ambition to become net zero by 2030 has turbo-charged clean green investment into the UK. Tritium continues to lead the way – and is well placed to make the most of the green industrial revolution.”

Lord Botham’s visit to Tritium included a tour of Tritium’s new, world-class testing facility, interactions with new charging technology in our testing bays, and a tour through our factory. Throughout these visits, the Sir Ian Botham learned about Tritium’s various points of differentiation, including how our fully sealed charger enclosures, liquid cooling, and small footprint help Tritium save customers up to 37% in total cost of ownership over ten years, compared to air cooled systems. Lord Botham also had a chance to check out Tritium’s latest modular technology, like the RTM and PKM, discovering first-hand how we’re developing products which are designed to push the limits of charging technology and achieve the highest reliability, while enabling more cost-effective operations and infrastructure deployment for customers.

It was such a privilege to host Lord Ian Botham at our facilities, and we look forward to hosting him again soon!