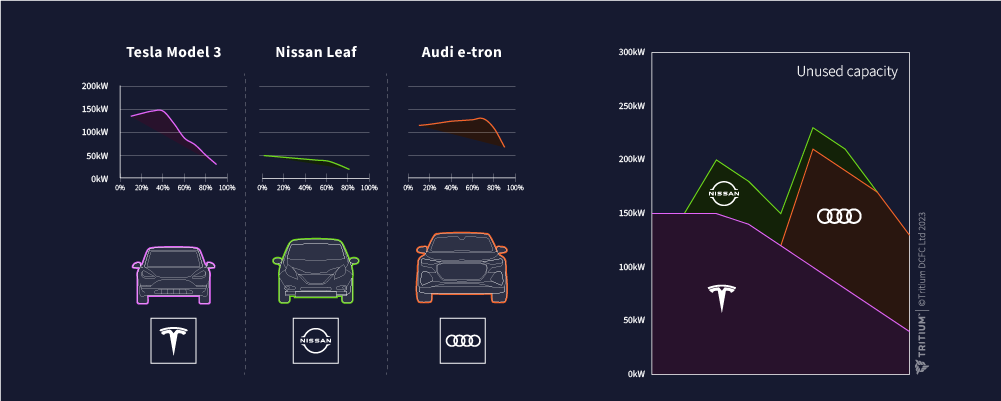

Electric vehicles (EVs) don’t all charge at the same rate. Some charge faster than others, and all of them charge at different rates over time. Even the fastest-charging passenger vehicles like the Audi e-tron GT do not draw their rated 270kW the entire time they’re plugged in to a DC fast charger. (Note: Large commercial vehicles like delivery trucks and buses can draw full power for most of the charging cycle.) That means you don’t need to deliver maximum power to every charger on your site at the same time. The chargers on your site can be networked and use load balancing to ensure EVs get the power they need when they need it—and you won’t have to outfit your charging site with gigawatts of power.

Charging a lithium-ion battery takes finesse—charge them too quickly or too much and they could overheat and become damaged. To prevent this, EVs use software to control the power delivery to the battery. Initially they can accept high levels of power, but as the battery charges up, charging levels drop to maintain battery health. Load balancing takes advantage of this difference in charging rates over time to deliver the right amount of power to EVs when it’s needed.

Load balancing lets you build a charging site now that meets the needs of EV drivers and your budget. You can build a site with multiple high-output DC fast chargers without the need to supply it with enough power to run all chargers at maximum power at the same time. This is crucial: You’ll save on utility-side infrastructure costs and you can upgrade site power when needed. This also expands the number of potential sites for your charging stations. Some sites may not have enough utility power now but will in the future. Load balancing lets you build a site now with a full complement of DC fast chargers and add more power capacity over time to meet future EV demands.

Tritium PKM150 chargers leverage the diversity of electric vehicle charging speeds via an innovative DC microgrid architecture and a proprietary algorithm to send the right amount of power to each charging station as required. The algorithm monitors various parameters, including available grid power, each vehicle’s requested power, and any active OCPP smart charging profiles, and dynamically shares power between all connected charging stations. Thanks to this load-balancing software and system design, four PKM150 chargers can share power from a single rectifier unit without the need for external load management solutions. This saves infrastructure and installation costs at the site.