As industrial campuses increasingly integrate electric vehicles into operations-whether for fleets, logistics, or employee commuting-safe and compliant EV charging infrastructure becomes essential. High-power DC fast chargers must perform reliably under continuous use, withstand challenging environmental conditions, and meet global safety standards. Tritium Charging, a leading manufacturer of DC fast chargers deployed in more than 50 countries, offers solutions specifically engineered to deliver safety, durability, and long-term performance across industrial environments.

This informational guide explores how safety, compliance, and reliability are built into Tritium’s charging hardware, modular platforms, and service ecosystem.

Why Safety and Compliance Matter for Industrial EV Charging

Industrial campuses face unique operational conditions that demand reliable and safe charging systems. Equipment may be exposed to dust, moisture, chemicals, vibration, and temperature extremes. Chargers often operate in high-traffic zones, near heavy machinery, or in areas where uptime is critical for fleet schedules.

Safe, compliant charging infrastructure ensures:

- Continuous operation with minimal downtime

- Protection from environmental exposure

- Reduced risk of malfunction or component failure

- Reliable fleet charging for operational continuity

- Long-term sustainability with manageable maintenance

Tritium’s design philosophy centers on building chargers that remain operational even in the harshest industrial conditions, supporting the safety and resilience requirements of large facilities.

Tritium’s Approach to Safety-Driven EV Charger Design

Tritium’s chargers are engineered to operate safely and reliably in environments where standard hardware may fail. Their systems are known for sealed enclosures, liquid cooling, and compact footprints-features that directly contribute to safety and compliance.

Sealed, Liquid-Cooled, IP-Rated Enclosures

Tritium chargers use sealed enclosures that protect internal components from dust, dirt, and moisture. This design minimizes risk in industrial settings where airborne contaminants and weather exposure are common.

Liquid cooling allows chargers to maintain optimal operating temperatures even under high loads or extreme heat. This contributes to consistent performance, prevents overheating, and reduces temperature-related failures.

Protection Against Harsh Conditions

Tritium’s chargers are designed for rugged environments, offering resistance to:

- Temperature fluctuations

- Outdoor weather exposure

- Dust and debris

- Environmental contamination

This makes them suitable for industrial campuses where charging equipment may be installed outdoors or near operational zones.

Built-In Monitoring for Safe Charging Performance

Tritium integrates monitoring capabilities and onboard intelligence that support operational safety. This includes internal control systems, protective mechanisms, and real-time reporting features that help ensure chargers operate within safe parameters at all times.

Global Certifications and Compliance Standards Built Into Tritium Chargers

Tritium designs its chargers to meet international safety and quality standards. Their hardware undergoes rigorous testing and certification to ensure compliance across global markets.

Why Global Certification Matters

Industrial campuses often operate across multiple regions or must meet diverse regulatory requirements. Certified charging equipment ensures:

- Consistency in product safety

- Protection against electrical faults

- Reliable performance across varied conditions

- Alignment with regulatory inspection needs

Standards Tritium Incorporates

Tritium designs its chargers to align with globally recognized safety and performance benchmarks, ensuring reliability across international markets. While specific compliance requirements may vary by product model and region, Tritium’s technology is engineered to meet the rigorous standards typically required for industrial installations worldwide. This commitment to quality helps facility managers maintain safer, more dependable charging infrastructure without needing to navigate complex certification details.

Safe and Scalable Infrastructure with Tritium’s Modular Platforms

Industrial campuses benefit from flexible charging systems that can grow as EV adoption increases. Tritium’s modular platforms support safe scalability without major operational disruption.

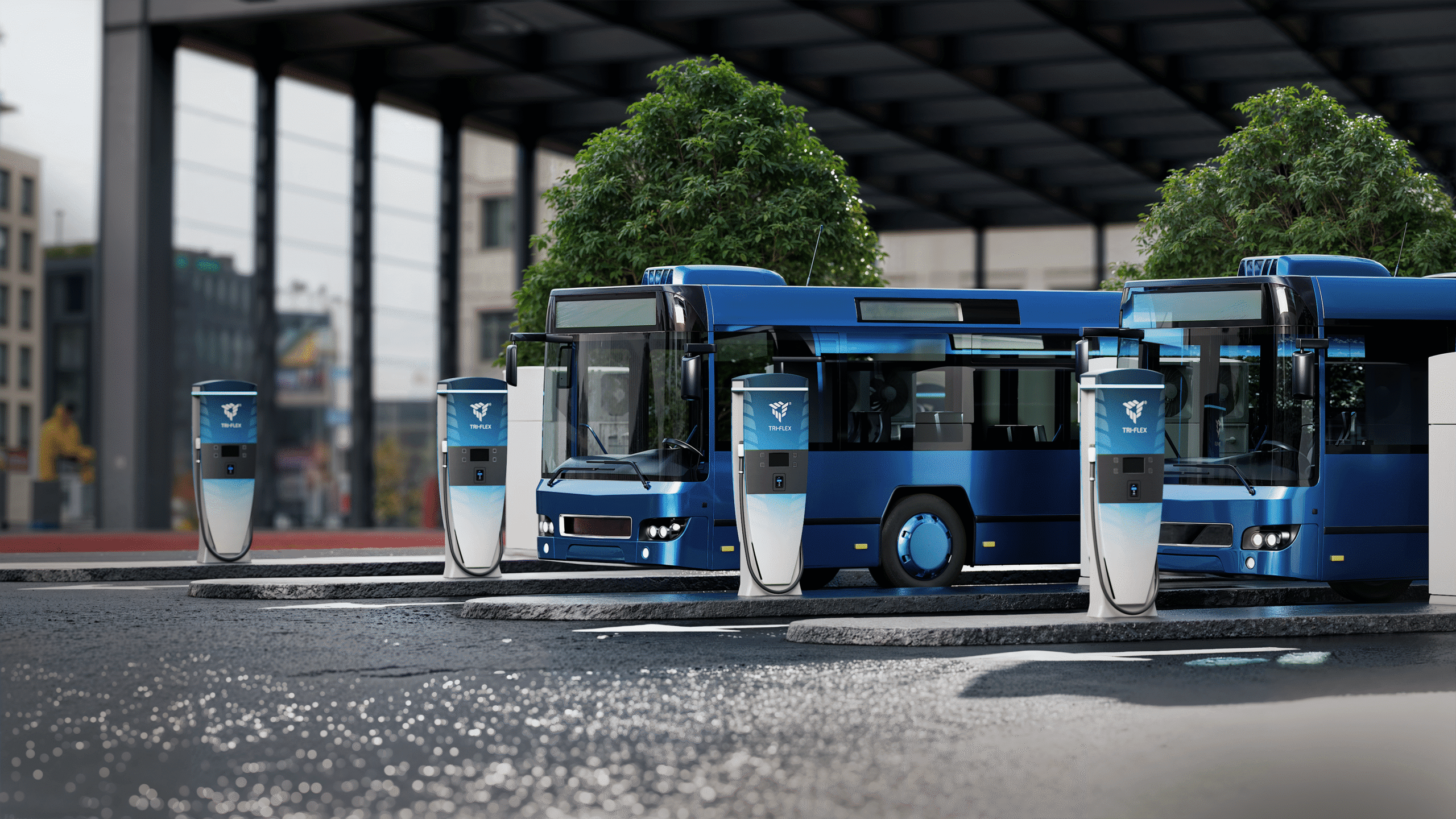

The TRI-FLEX Distributed Charging Architecture

One of Tritium’s standout innovations is the TRI-FLEX platform: a distributed architecture designed to power multiple charge points efficiently. It centralizes power modules within a single power cabinet and distributes energy to satellite chargers.

This structure offers several safety and compliance benefits:

- Reduced equipment footprint

- Simplified installation

- Scalable deployment without rewiring

- Easy maintenance access

- Consistent performance across multiple chargers

By consolidating power electronics, TRI-FLEX supports high-power charging while minimizing complexities associated with large installations.

Streamlined Compliance for Expansion

As industrial requirements grow, Tritium’s modular systems make it easier for facilities to increase charging capacity while maintaining regulatory compliance and operational safety.

Charger Reliability as a Core Component of Safety Compliance

Reliability is essential for safety. Frequent downtime, system malfunctions, or environmental failures can pose operational challenges and potential risks.

Tritium focuses heavily on:

Proven Engineering and High Uptime

Tritium’s long-standing presence in the EV charging industry and deployments across more than 50 countries reflect their focus on durability and continuous performance. Their systems are built for long-term stability, even under high usage rates typical of industrial fleets.

Rugged Construction for Industrial-Grade Use

Tritium chargers are specifically engineered for:

- Constant exposure

- Long operating hours

- High charging volumes

- Outdoor and mixed-environment installations

This reliability helps industrial campuses reduce risk and maintain consistent operational output.

Installation, Commissioning, and Site Readiness Services by Tritium

Proper installation is integral to safety and compliance. Tritium provides professional services to ensure their chargers are deployed correctly and safely across industrial campuses.

Professional Commissioning

Tritium’s commissioning services ensure that every charger is installed correctly, configured properly, and functioning reliably from the start. This reduces early-stage faults and ensures compliance with hardware specifications.

Site Design and Readiness Support

Tritium assists with:

- Site evaluation

- Charger placement recommendations

- Integration of chargers into existing infrastructure

- Power distribution planning

These measures help create a safe and efficient charging zone that aligns with facility operations.

Ensuring Long-Term Safety Through Proper Setup

Correct installation is foundational for compliance. Tritium’s support team ensures that chargers are set up according to design requirements, contributing to long-lasting, low-risk operation.

Ongoing Maintenance and Remote Monitoring for Compliance Assurance

Safety and compliance require continuous attention. Tritium offers ongoing services to ensure chargers stay in optimal condition.

Preventive Maintenance Programs

Tritium’s maintenance services include:

- Regular inspections

- Component checks

- Software updates

- Repair and replacement support

- Performance assessments

Preventive care extends equipment life and prevents issues before they become safety risks.

Remote Diagnostics and Support

Many Tritium chargers include connected services that allow:

- Real-time performance monitoring

- Remote troubleshooting

- Usage reporting

- Proactive detection of anomalies

Remote support enhances safety by enabling early identification of irregularities that could compromise compliance or performance.

How Tritium Supports Industrial Campuses in Meeting Safety Expectations

Tritium’s holistic approach-combining rugged hardware, global certifications, modular scalability, and professional service support-makes it easier for industrial campuses to maintain safety and compliance throughout their charging infrastructure.

Industrial facilities benefit from:

- Equipment built for extreme and demanding environments

- Chargers designed to operate reliably with minimal downtime

- Scalable systems that support long-term fleet growth

- Support services that maintain consistent compliance

- Globally certified hardware suitable for multi-regional operations

Conclusion

For industrial campuses transitioning to electric fleets or expanding charging capabilities, choosing safe, reliable, and compliant charging systems is essential. Tritium Charging delivers solutions specifically engineered for industrial-grade performance, integrating rugged construction, globally compliant design, modular scalability, professional installation, and ongoing maintenance support.

Partnering with Tritium Charging, industrial facilities can build a robust EV charging ecosystem that ensures safety, supports continuous operations, and meets long-term sustainability goals.

FAQ

1. What makes EV charging safety important for industrial campuses?

Safe charging ensures reliable fleet operation, reduces downtime, and protects equipment in harsh environments.

2. How does Tritium enhance charger safety in industrial conditions?

Tritium uses sealed, liquid-cooled, IP-rated designs that protect chargers from dust, moisture, and temperature extremes.

3. Why does compliance matter for industrial EV charging installations?

Compliance helps facilities meet regulatory expectations while ensuring dependable, low-risk charging performance.

4. How do Tritium’s modular platforms support safe scalability?

Their modular architecture enables easy expansion while maintaining consistent performance and simplified installation.

5. What services help maintain long-term safety and reliability of Tritium chargers?

Professional installation, preventive maintenance, and remote monitoring ensure chargers operate safely over time.